Quick setting gauge for engraving tools.

Comp. GCIS or EHT

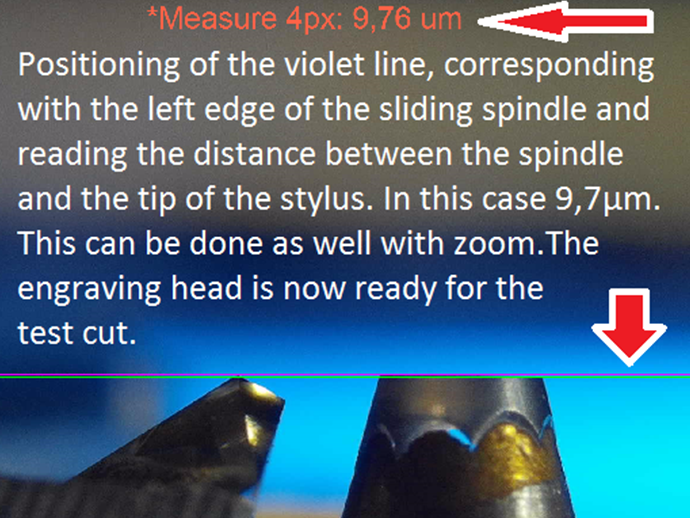

- Perfect adjustment of the gravure tools in micrometers, according to the skills of the operator.

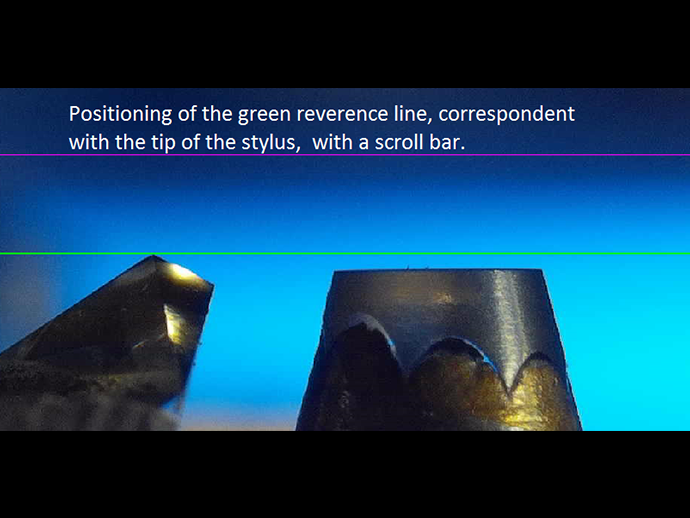

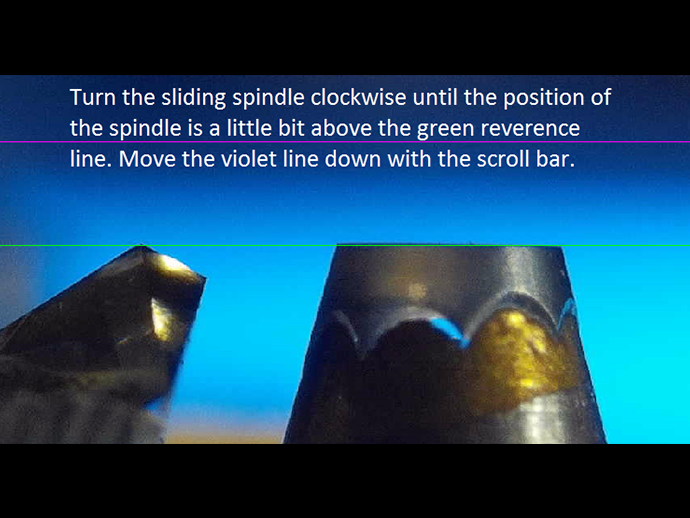

- In a matter of seconds it is possible to reach the ideal position of the engraving-tools, magnified on a monitor by a microscope and a camera with a magnification of 200times.

- No more scratches of lines with the unprotected tip of the stylus on top of the production cylinder, like today via using the HelioSprint head.

- No more unwished scratches inside or outside of the printing material.

- Direct engraving of the test-cut after setting the stylus into the right vertical position and the settings with the new gauge in an blink of an eye.

- Positioning of the engraving tools of all commercially available engraving-heads, as well of the A-head which is not possible today with the previous available tools.

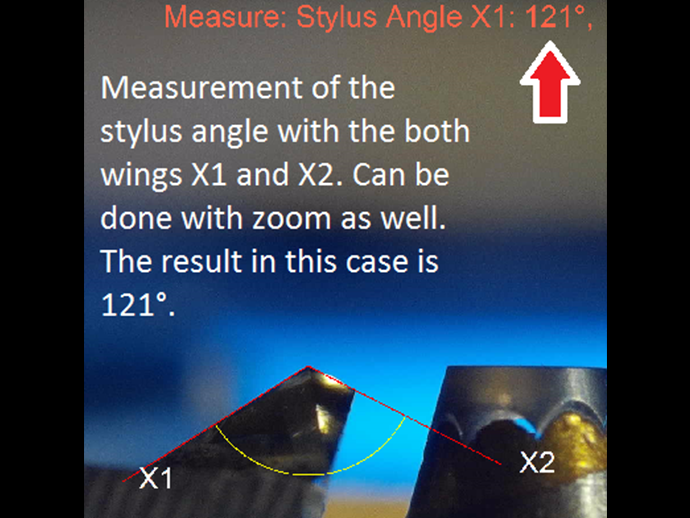

- Quick measurement of the stylus-angle and checking the condition of 2 cutting edges.

- Avoidance of the engraving repetition due to the fact, that the wrong stylus has been in use.

- Standardized work-flow for all machine-operators.

- Time saving.

- Simple operating.

Products EHT

- Gravure head 8khz.

- Stylus Setting Gauge.

- Filter for HelioSprint.

- Spare parts for the stylus setting gauge.

- Puller for the stylus.

- Spare parts for the sliding shoe spindle.

- Dumping plate for HelioSprint.

- Modifying of an old setting gauge into a contemporary one.

Gravure head 8khz

Stylus Setting Gauge

Filter for HelioSprint

Spare parts for the stylus setting gauge

Puller for the stylus

Spare parts for the sliding shoe spindle

Dumping plate for HelioSprint

Modifying of an old setting gauge into a contemporary one